TPU hot melt web BTPU98

The BTPU 98 hot melt web is a non-woven hot melt adhesive that can be easily or continuously operated.This product can be widely used in various types of fabrics, paper, polymer materials and metals. The weight per square meter is from 8-120 grams.

Typical use

Ingredients: Polyurethane

Clothing industry fabric bonding

Adhesive foam and sheet bonding for the automotive industry

Indoor product fabric bonding

Multi-layer bonding of filter materials

Luggage industrial fabric bonding

architectural decorative fabric bonding

Physical and chemical properties

| Appearance |

white |

| Melting range (°C) |

103-110 |

Application characteristics

| Bonding parameter (reference value) |

| Pressing temperature (°C) |

130 |

| Pressure (MPa) |

0.2 |

| Time (s) |

10-20 |

1. Strong bonding ability and washing ability

2. High molecular strength, not easy to plasticize and deform

3. High bonding strength to fabrics and foams

4. good air permeability, not easy to aging and yellow

Note: According to the bonding material, the pressing conditions need to be adjusted appropriately.

Precautions

Keep away from children.

If you accidentally touch your eyes, rinse immediately with water and seek medical attention if you

are serious.

If you accidentally touch the skin, rinse with water.

It is recommended to use in a well ventilated area.

Please refer to the MSDS of this product for product safety information.

Product specifications

Weight 25g, or customized according to customer requirements.

Reference usage

1. Hot melt adhesives require hot pressing bonding.

2. If it is a combination of two thin flexible materials, the material 1 / hot melt adhesive film /

material 2, stacked together, using a flat press or flat laminating machine, hot pressing bonding,

reference temperature125- 140 ° C, pressure 0.2 MPa, time 12 seconds, the specific pressing conditions

need to be adjusted according to customer's actual conditions.

3. If it is a thick and rigid material, the hot melt adhesive can be placed on the surface of the

thick rigid material and baked together in an oven at 150 ° C. After the hot melt adhesive film is

completely melted, the two materials are bonded. Together, the baking temperature can be adjusted

according to the customer's actual situation.

4. Thinner rigid materials can also be pressed with a flat press, such as a thin aluminum plate and a

non-woven fabric.

Transportation and storage

Hot-melt adhesives are non-hazardous materials. They should be handled gently during transportation

to prevent exposure to sunlight, rain, heat and heavy pressure. It is forbidden to use iron hooks

during loading and unloading to protect the packaging.

The product should be stored in a cool, ventilated, dry place, protected from sunlight, rain, high

temperature, etc., and the height of the stack should not exceed 3 layers. The storage environment

should be stored in a cool and dry place at 0-30 °C (humidity ≤ 70% RH).

Storage period: 12 months from the date of production.

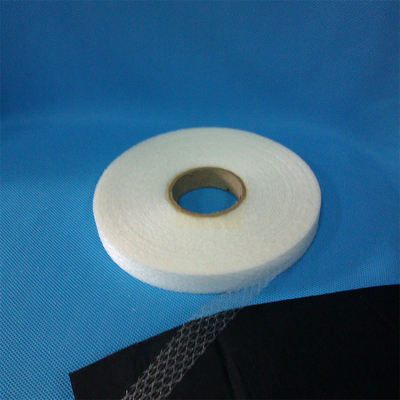

Packing image:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!