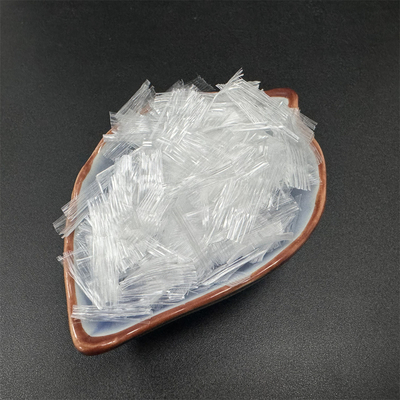

12-20mm Polypropylene Mesh Fiber Improves The Quality And Strength Of Concrete Engineering

Instruction:

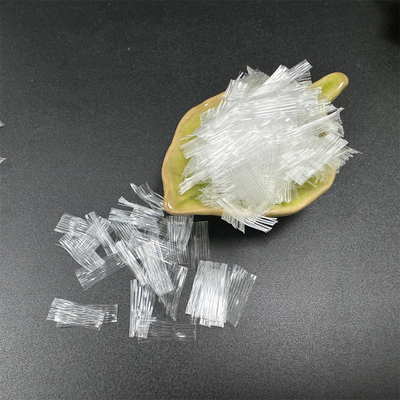

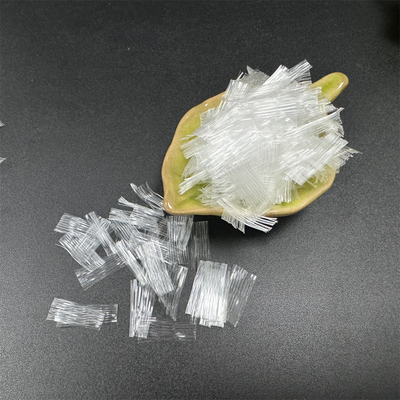

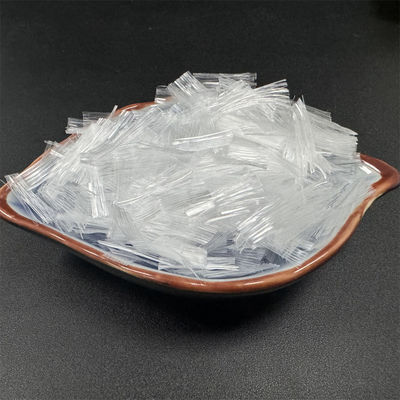

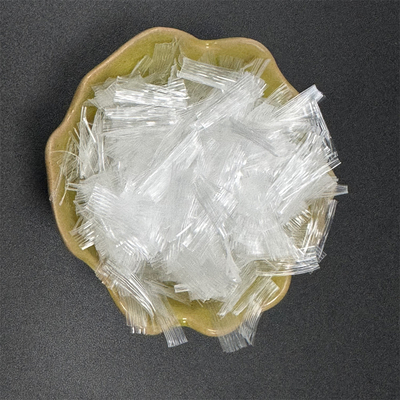

StrongCrete PP Mesh Fiber is made of 100% virgin homopolymer polypropylene as raw material, through extrusion, stretching, netting, surface modification treatment, short cutting and other processes. The appearance of pp mesh fibers is a network structure formed by the intersection of multiple filaments, When the pp mesh fibers are put into concrete the reticulated fibers are extruded and torn into single wires with hooks at both ends and are interwined and distributed in many directions which enhances the bonding force between the fibers and concrete.

A large number of pp mesh fibers are distributed in concrete in three-dimentional form which provides reticulate supporting effect, fundamentally changes the crack resistance, impact resistance, fatigue resistance and wear resistance of concrete, greatly improves the toughness and deformation ability of concrete and thus greatly improves the quality of concrete engineering.

1. Length : The commonly used pp mesh fiber length in concrete is 20mm, and the commonly used pp mesh fiber length in shotcrete is 10mm

2. Ratio Design: Usually the fiber content of concrete is 0.9kg/m3, the fiber content of bridge waterproof layer is required to be 1.35-1.8kg/m3, the tunnel spray concrete is the same, and other materials remain unchanged. Among a series of active composite materials such as silica fume, pulverized coal, grinding slag, zeolite powder and fiber, fiber has a relatively good effect on concrete.

3. Mixer Adoption:Double-axis horizontal compelling mixer and self-dropping cylinder mixer, Double-axis horizontal compelling mixer is better.

4. Mixing Process:Crushed stones, fibers and sands will be put into the mixer in turn. After two minutes of mixing, the fiber is fully developed, and then add cement and water, and stir normally. The material can be put in as usual, but the mixing time should be appropriately extended to allow the PP Mesh Fiber to be fully mixed.

5. Stirring Time: Usually 2-3 minutes after adding PP Fiber Mesh Form, the purpose is to make the fiber fully spread into monofilament or net fully spread, thus enhancing the strength of the concrete.

Function:

|

Increase seepage resistance

|

Prolong endurance

|

Improve steel protection

|

|

Increase cracking resistance

|

Increase fire resistance

|

Strengthen spurt & fatigue

|

|

Improve tensile, bending & folding strength

|

Improve plastic deformity

|

Strong acid & alkali resistance and good endurance

|

Specifications:

|

Raw Material

|

100% virgin PP

|

Fiber type

|

Fibrillated Mesh

|

|

Crack Elongation

|

>10%

|

Melting Point

|

160℃

|

|

Density

|

0.91g/cm3

|

Tensile Strength (Mpa)

|

>560

|

|

Fiber Diameter

|

0.035mm

|

Fiber length

|

12,19,38,54mm...

|

|

Elastic Modulas

|

>3500Mpa

|

Width

|

5mm

|

|

Alkali & Acid resistance

|

Strong

|

Ways of packing

|

PE bag or paper bag

|

Application:

1.PP mesh fiber for concrete reinforcement

2.PP mesh fiber for mortar reinforcement

3.PP mesh fiber for anti-cracking resistance

Packing:

1kg net each PE bag, 10kgs per plastic woven bag

Certification:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!