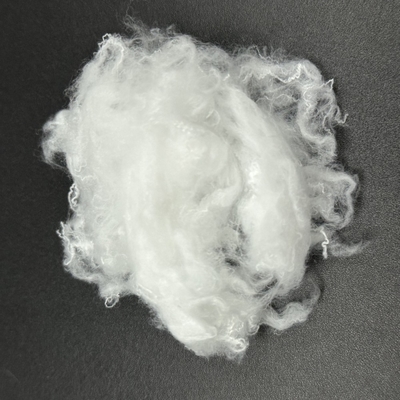

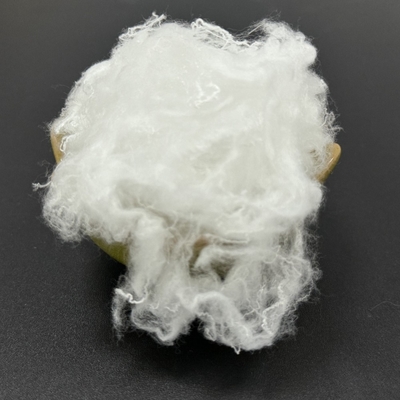

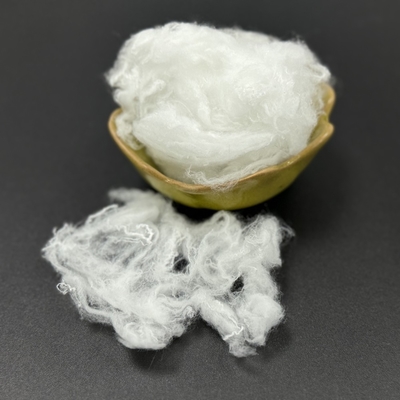

PA66 And PA6 Type Semi Dull Nylon Fiber For Non-Woven Fabrics

Nylon Fiber Product Description:

Nylon, the chemical name is polyamide fiber (Polyamide, PA for short). The main varieties of nylon are nylon 6 (PA6) and nylon 66 (PA66).

Nylon Fiber Character:

1. Nylon fiber have abrasion resistance: The abrasion resistance of polyamide fiber is the best among all textile fibers. Under the same conditions, its abrasion resistance is 10 times that of cotton, 20 times that of wool, and 50 times that of Rayon. If 15% polyamide fiber is blended into wool or cotton spinning, its abrasion resistance is 3 times higher than that of pure wool or cotton.

2. Nylon fiber have resilience: Polyamide fiber has excellent resilience. When the elongation of long fiber is 10%, its elastic recovery rate is 99%, while polyester is 67% under the same conditions, and rayon is only 32%. Can withstand tens of thousands of times of bending without breaking.

3. Nylon fiber strength: The strength of polyamide fiber is 1-2 times higher than cotton, 4-5 times higher than wool, and 3 times higher than viscose fiber.

4. Nylon fiber optical properties: Polyamide fiber has birefringence, and the birefringence varies greatly with the extension ratio, so the surface gloss is higher, usually by adding titanium dioxide to the polymerization to extinction.

5. Nylon fiber unit weight: Nylon fabric is a light fabric, which is only listed after polypropylene and acrylic fabrics in synthetic fiber fabrics. Therefore, it is suitable for making mountaineering clothes, winter clothing, etc.

6. Nylon fiber unit weight dyeability: The dyeability of polyamide fiber is more difficult than natural fiber and rayon, but it is still easier to dye than other synthetic fibers. Generally, it is dyed with acid dyes.

7. Nylon fiber unit weight chemical resistance: Polyamide fiber has good alkali resistance, but poor acid resistance. Under normal room temperature adjustment, it can withstand 7% hydrochloric acid, 20% sulfuric acid, 10% nitric acid, and 50% Soaked in caustic soda, the result is not corrod.

Nylon Fiber Specification:

| Breaking Strength |

5.07CN/dtex |

Crispation Number |

10 pcs/25mm |

| Elongation at break |

61.31% |

Crimp Percentage |

8.6% |

| Linear Density |

1.67-3.3dtex |

Oil Content |

0.33% |

| Length |

38-65mm |

Moisture Regain |

4.35% |

| Specific Resistivity |

3.2X 10 8 |

Dry heat shrinkage rate |

5.75% |

| Very long fiber rate |

1.1% |

Over-length fibre |

7.6 mg/100g |

| Flaw |

<25 mg/100g |

Strength CV value |

6.17 % |

| Breaking Strength |

5.71CN/dtex |

Crispation Number |

13 pcs/25mm |

| Elongation at break |

70.53% |

Crimp Percentage |

8.85% |

| Linear Density |

1.5D-3D |

Oil Content |

1.01% |

| Length |

38-65mm |

Moisture Regain |

4.35% |

| Specific Resistivity |

1.3X 10 9 |

Dry heat shrinkage rate |

6.24% |

| Very long fiber rate |

0.4% |

Over-length fibre |

0.8 mg/100g |

| Flaw |

0 mg/100g |

Strength CV value |

6.17 % |

Nylon Fiber Packing:

Around 210kg per bale, 88bales on a 40HQ

Nylon Fiber Related Goods:

PLA FIBER PEEK FIBER PP MESH FIBER

Certification:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!