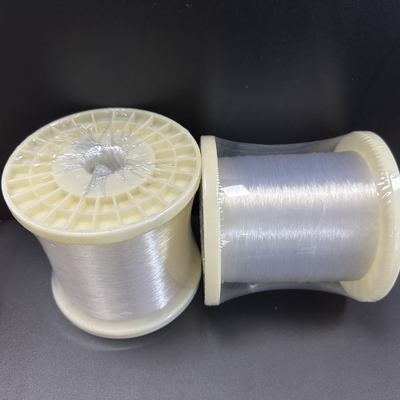

Wholly Aromatic Fiber Polyetheretherketone (PEEK) Fiber For Aerospace And Composite Materials

Properties:

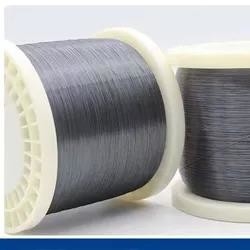

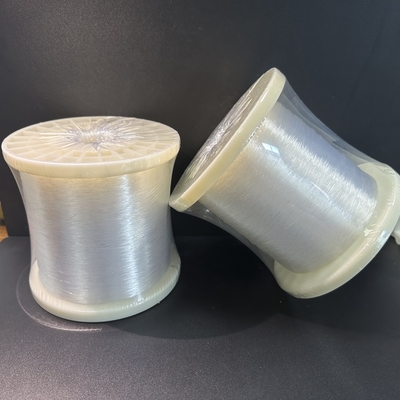

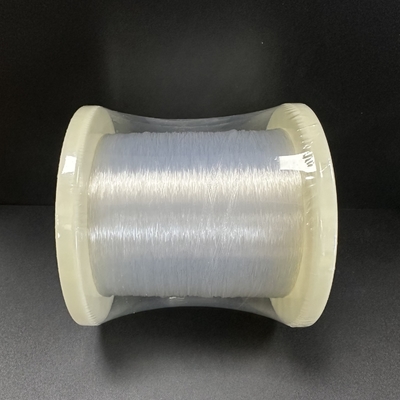

PEEK specialty fiber is produced by high temperature melt spinning of PEEK resin.

1. High temperature resistance: UL temperature index 250℃.

2. High strength: Purity resin up to 94MPa, fiber enhanced up to 210MPa.

3. Chemical resistance: except sulfuric acid, almost insoluble in any regular chemical reagents.

4. Irradiation resistant: resistant to 109 rad, equivalent nuclear reactor radiation intensity.

5. Creep resistance: especially high temperature creep resistance, equivalent nylon normal temperature

endurance at 150℃,

6. High flame retardancy: can meet 94V-1 of 0.3mm thick, can meet 94V-0 of 1.5mm thick,

7. Only produce H2O and CO2 when fully burned, does not produce any toxic gas.

8. Excellent high temperature hydrolysis resistance: there is still enough endurance at more than 200℃.

9. High tensile strength of 400 ~ 700MPa: monofilament rupture strength about 25~40cN/tex,

multifilament up to 65 cN/tex.

10. Elongation 20%~40%

11. Modulus 3~6GPa,

12. LOI value 35,

13. Melting point 334~343℃, Long-term use temperature of 250℃.

Specification:

| Available Monofilament Diameter (mm)+/-0.03 |

| 0.06 |

0.07 |

0.10 |

0.15 |

0.20 |

0.25 |

0.28 |

0.30 |

0.35 |

0.38 |

| 0.40 |

0.45 |

0.50 |

0.55 |

0.60 |

0.70 |

0.80 |

0.90 |

1.00 |

/ |

| Available Multifilament Types (D/F) +/-20D |

| 150/30 |

200/30 |

250/60 |

300/60 |

400/60 |

450/60 |

| 500/ 120 |

600/ 120 |

800/ 120 |

900/ 120 |

1000/ 120 |

/ |

Introduction and Application:

1. PEEK fiber is a wholly aromatic fiber with the presence of ether bonds and ketone bonds, which makes the fiber's high temperature resistance, friction and corrosion resistance much higher than conventional fibers.

2. PEEK fiber is mainly used in aerospace, composite materials for structural components required for weaponry, braided sheath for aerospace high-performance wire and cable, and dry canvas for paper

making machinery in civil fields, heat-resistant filter cloth, Heat resistant and corrosion resistant textile tape, Composite materials (mixed with glass fiber, carbon fiber), high temperature resistant materials for the energy industry

Certification:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!